Efficient linear solvers for battery aging simulations

In many simulation applications, the choice of optimal methods and parameters for the linear solver depends on the specific simulation, for example, material properties, problem size, parallelism, and the like. While it is usually possible to find a fixed linear solver strategy that fits a simulation application very well, final adjustments to the concrete simulation are difficult to determine in advance. This is where the autonomously acting solver control comes in: Instead of a fixed linear solver strategy, a certain range of eligible methods and parameter bandwidths is given. Within these possibilities, our solver software Algebraic Multigrid Methods for Systems (SAMG) then independently determines the best settings in each case. For this purpose, evolutionary learning methods and surrogate models are used.

Example application: Simulation of battery aging

The autonomous solver control enables the use of iterative linear solver methods from the SAMG library in the Battery Simulation Studio software (BaSiS) at the Fraunhofer IEE.

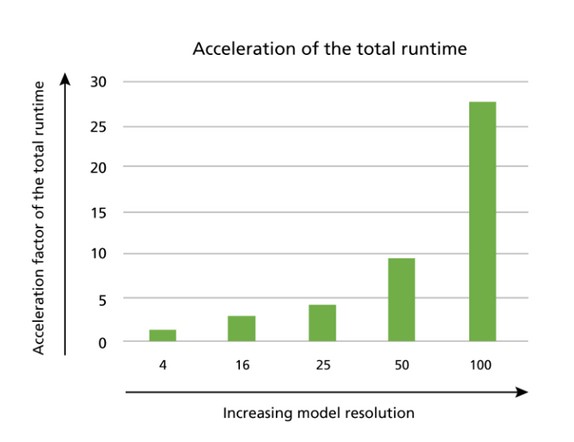

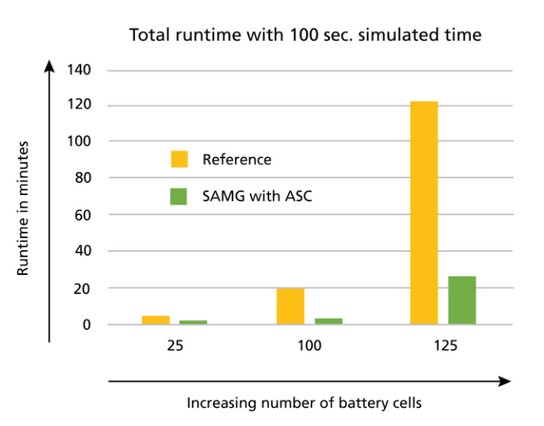

The complexity of the physical and electrochemical processes of a battery often leads to ill-conditioned equation systems. This, together with the range of different battery configurations, makes it practically impossible to specify a single iterative solution method. Therefore, until now, only the use of direct solver methods was possible. By controlling in SAMG, iterative single-level methods can now be used here and provide a significant reduction in computation time compared to direct solver methods.

This is particularly relevant in the simulation of aging processes, which consider long overall time periods. Here, the simulation must be performed in a fraction of the simulated time to be meaningful.

Accelerating battery aging simulations through Machine Learning methods

The ability to perform a comprehensive aging simulation of battery packs with a practical number of batteries has not been feasible to date. The method developed in the project allows not only an, within the given limits, autonomous parameter tuning, but also the use of linear solver strategies.

These are only robust in the majority of cases of an application, but very performant. If the robustness is not sufficient, the solver control provides fallback positions, provided it has been configured accordingly.

In principle, all procedures and parameters of the SAMG library can be considered in the preselection to be defined. In special cases, pre-selections implemented in SAMG can also be used. In general, this preselection can be specified by an XML input.

Autonomous Solver Control (ASC) - applicability without expert knowledge

In the research project "ELeBa", of the Fraunhofer Institutes IEE and SCAI, the solver control in SAMG was further developed. The learning control (ASC) allows to replace expensive direct solver methods by fast iterative ones and thus ensures easy applicability without expert knowledge. Robust and efficient settings are automatically selected per battery type and the range of applications is increased.

Linear solution methods are still the efficiency bottleneck, as aging simulations of only a few batteries at a time are feasible, but battery packs consist of hundreds to thousands of batteries. With sustainability and the accompanying increase in e-mobility, increasing the efficiency of the method is becoming increasingly important as larger battery packs are used. With ASC, it is now possible to efficiently simulate battery aging even of large battery packs.

Research Center Machine Learning

Research Center Machine Learning