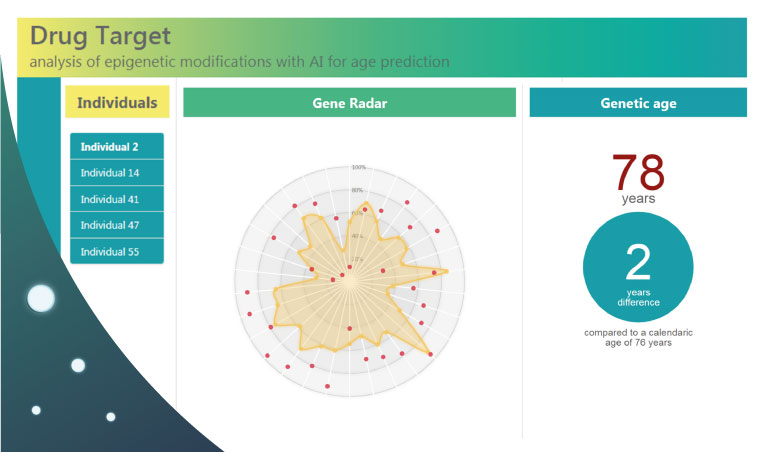

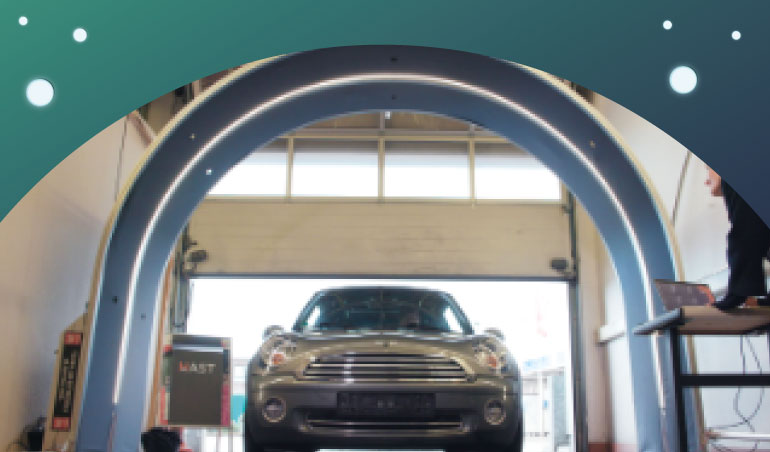

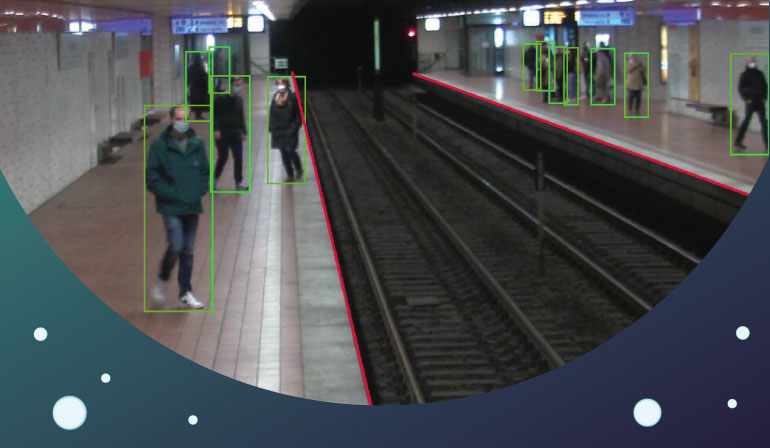

The Fraunhofer CCIT Technology Hub Machine Learning engages in interdisciplinary projects in diverse application areas such as production technology, quality control, process monitoring, or dialog systems and media analysis. The center cooperates with partners from business and industry as well as with universities and research centers. Discover the variety of our projects here.

Are you interested in an innovative Machine Learning solution for your company? We look forward to talking with you about individual application possibilities.

Research Center Machine Learning

Research Center Machine Learning